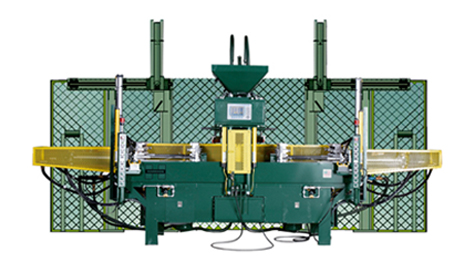

Auto-Unload Core Machines

Unload Automation Core Making Processes:

- Cold Processes supported with automation, for all common cold cure processes.

- Hot Processes supported with automation, for Shell, Warm Box, and Hot Box processes.

Productivity & Utilization

- Increases Operator Output: One Operator can run 2 Pick-and Place cells or 2 Robotic Cells.

- Automatic Operation: the machine(s) run continuous production for predictable results and maximum productivity.

- Constant Production one station remains in production during other station change-over.

- Quick Change System: available, change boxes in just a few minutes instead of the better part of an hour.

- Advanced Process Control: helps to make the cycle more efficient and consistent facilitating an automatic operation.

- High Speed Operation: high efficiency pneumatics enable faster Dual Station machine times than most other single station machines.

- Higher Productivity: because of the nature of HMC Dual Station System machines have a much shorter machine time part of the cycle.

Auto-Unload Core Machines - Repeatability

- Automatic Operation with Machine Driven Process

- Optimized Recipes Management

- Automatic Process Monitoring

- Quick Box Change Systems available

Unparalleled Flexibility

- Dual Station Multiple Operational Modes suit the constantly changing demands of most Foundries by running at the same time:*

- (1) Auto-Unload Core Machines - High Volume Job with 2 Tools

- (2) Medium Volume Jobs

- (2) Customers at Same Time.

- Both Parts of a (2) pc. Core

- Three Piece Box capability

- Large Core on (1) Station, Small Core(s) on Other Station

- Automatically Runs Multiple Short Cycles on (1) Station to (1) Long Cycle on Other Station

- Shell - Hollow Core(s) on (1) Station & Solid on the Other Station, or Same on Both Stations

- Small Box on (1) Station & Large on the Other Station, or Same on Both Stations

Auto-Unload Core Machines - Reduced Energy & Emissions

- Superior Productivity, Utilization, and Flexibility: equal fewer Harrison machines are required to meet capacity demand.

- Fewer Machines equal less core making energy used.

- Lower Energy Usage equals less related energy consumption emissions.

- Cold Process - Smart Cure System reduces the amount of binder needed reducing cost and emissions.

- Lower Emissions equals less cost for regulations compliance and lower remediation expenses.

- Higher Productivity & Fewer Machines means more cores per energy & labor unit equals lower operating cost.

- Lower COST-per-CORE equals a quick payback & higher margins equal an increased Competitive Advantage.

Auto-Unload Core Machines - Specs:

| Model | Max Box Capacity | Blow Cap. |

|---|

| 1016- | 10”H x 16”W x 6”D | 20lbs / 5L |

| 1616- | 16”H x 16”W x 10”D | 35lbs / 9L |

| 1818- | 18”H x 18”W x 10”D | 40lbs / 10L |

| 1824- | 18”H x 24”W x 10”D | 57lbs / 15L |

| 2424- | 24”H x 24”W x 10”D | 70lbs / 20L |

| 2430- | 24”H x 30”W x 12”D | 95lbs / 25L |